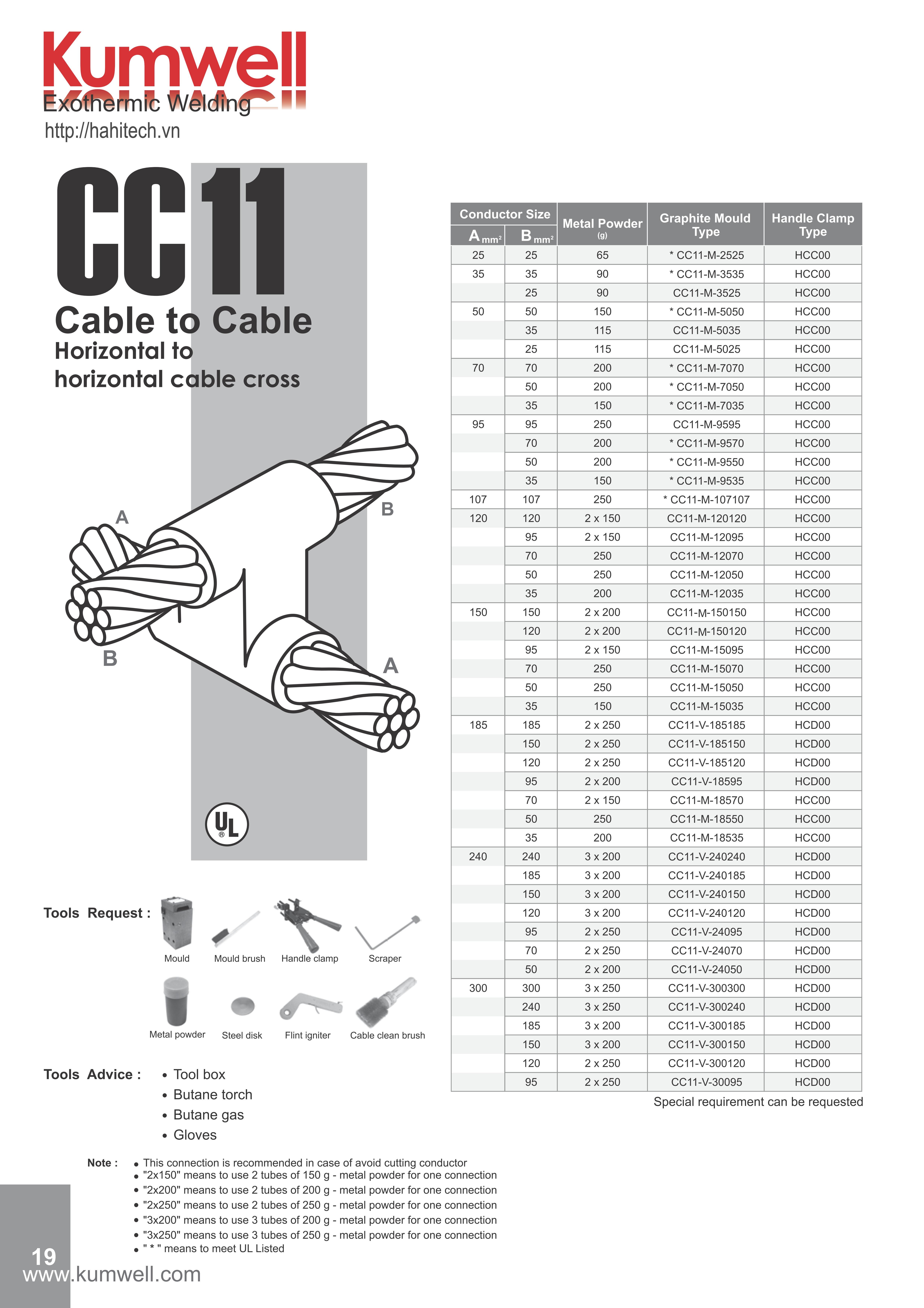

CC11-M-15095, khuôn hàn hóa nhiệt chữ thập cáp đồng M150 - 150mm2 với cáp đồng M95 - 95mm2, cáp chồng cáp không cần cắt cáp

CC11-M-15095, khuôn hàn hóa nhiệt chữ thập cáp đồng M150 - 150mm2 với cáp đồng M95 - 95mm2, cáp chồng cáp không cần cắt cáp

Download tài liệu thuốc hàn hóa nhiệt Kumwell, khuôn hàn hóa nhiệt Kumwell

Download tài liệu thuốc hàn hóa nhiệt Kumwell, khuôn hàn hóa nhiệt Kumwell

1  Kumwell exothermic welding connections have been tested, inspected and qualified for successfully meeting qualifications and international reliable standards of UL 467 – Standard for Grounding and Bonding Equipment, IEEE 837 – Standard for Qualifying Permanent Connections used in substation grounding, IEC 62561-1:2012 Lightning Protection Systems Component (LPSC) for Connection Components and ISO 9001:2008 Quality Management System.

Kumwell exothermic welding connections have been tested, inspected and qualified for successfully meeting qualifications and international reliable standards of UL 467 – Standard for Grounding and Bonding Equipment, IEEE 837 – Standard for Qualifying Permanent Connections used in substation grounding, IEC 62561-1:2012 Lightning Protection Systems Component (LPSC) for Connection Components and ISO 9001:2008 Quality Management System.

In addition, Kumwell emphasizes on product safety with our exothermic welding process. For the starting and weld metal powder, we ensure that the material contains non-toxic, heavy metal, and non-self-ignite. Also when heated the weld metal powder for bonding connections, it gives steady burn without pop and fire out, consistency of color, no slag and porosity.

.jpg)

2 Kumwell exothermic welding connections have been tested, inspected and qualified for successfully meeting qualifications and international reliable standards of UL 467 – Standard for Grounding and Bonding Equipment, IEEE 837 – Standard for Qualifying Permanent Connections used in substation grounding, IEC 62561-1:2012 Lightning Protection Systems Component (LPSC) for Connection Components and ISO 9001:2008 Quality Management System.

In addition, Kumwell emphasizes on product safety with our exothermic welding process. For the starting and weld metal powder, we ensure that the material contains non-toxic, heavy metal, and non-self-ignite. Also when heated the weld metal powder for bonding connections, it gives steady burn without pop and fire out, consistency of color, no slag and porosity.

3 Kumwell exothermic welding connections have been tested, inspected and qualified for successfully meeting qualifications and international reliable standards of UL 467 – Standard for Grounding and Bonding Equipment, IEEE 837 – Standard for Qualifying Permanent Connections used in substation grounding, IEC 62561-1:2012 Lightning Protection Systems Component (LPSC) for Connection Components and ISO 9001:2008 Quality Management System.

In addition, Kumwell emphasizes on product safety with our exothermic welding process. For the starting and weld metal powder, we ensure that the material contains non-toxic, heavy metal, and non-self-ignite. Also when heated the weld metal powder for bonding connections, it gives steady burn without pop and fire out, consistency of color, no slag and porosity.

4 Kumwell exothermic welding connections have been tested, inspected and qualified for successfully meeting qualifications and international reliable standards of UL 467 – Standard for Grounding and Bonding Equipment, IEEE 837 – Standard for Qualifying Permanent Connections used in substation grounding, IEC 62561-1:2012 Lightning Protection Systems Component (LPSC) for Connection Components and ISO 9001:2008 Quality Management System.

In addition, Kumwell emphasizes on product safety with our exothermic welding process. For the starting and weld metal powder, we ensure that the material contains non-toxic, heavy metal, and non-self-ignite. Also when heated the weld metal powder for bonding connections, it gives steady burn without pop and fire out, consistency of color, no slag and porosity.

CC11-M-15095, khuôn hàn hóa nhiệt chữ thập cáp đồng M150 - 150mm2 với cáp đồng M95 - 95mm2, cáp chồng cáp không cần cắt cáp